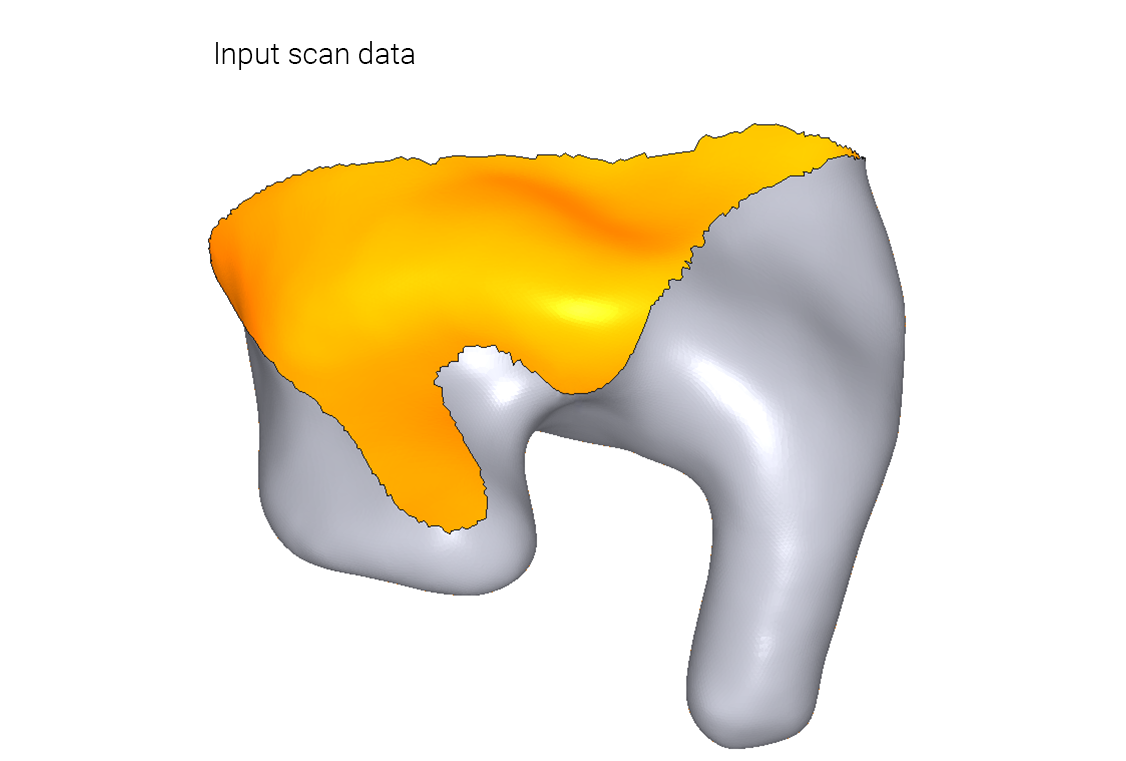

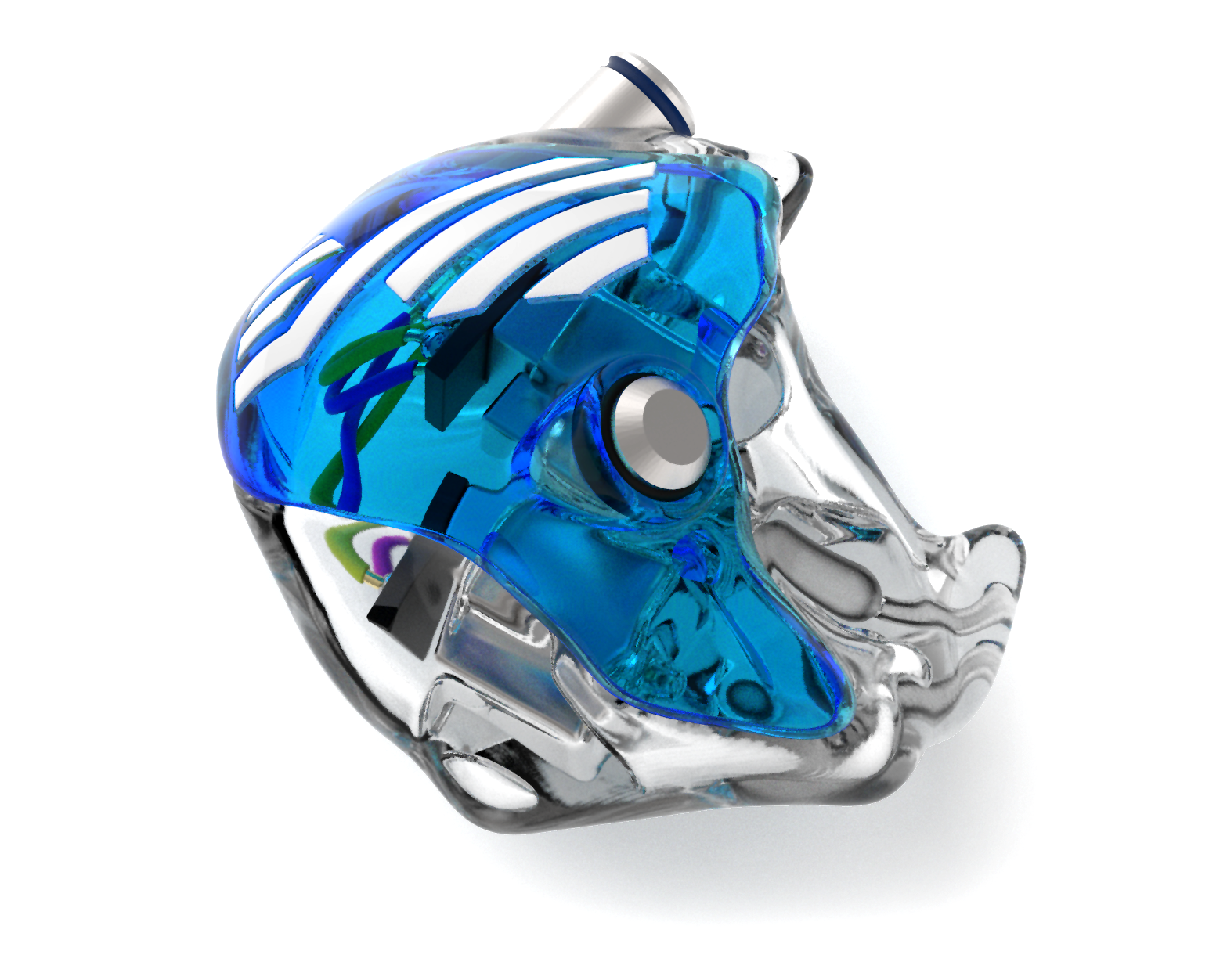

Custom in-ear monitors are a class of headphone most commonly used by professional musicians due to both their incredible audio quality and equally high price. CIEMs are made by taking 3D scan data of a client's inner ear then having a technician use various CAD programs to manually create an enclosure from this data. The finished model is 3D printed, components are hand fit inside the enclosures and then custom caps are made for each headphone to seal it off.

The number of specialists involved results in a long lead time and high price for each set of custom monitors.

In this project an automated pipeline was created that generates all the CAD data without the need of a specialist. From a simple UI a user selects the 3D scan data and the desired internal hardware configuration. Our software then runs a series of simulations to fit all components within the CIEM enclosure and create the necessary mounts for the driver hardware.

This eliminates the need for a CAD operator and drastically decreases the assembly time of the output parts.